Aerosol composition

Aerosols have four major components: propellant, medicament, valve system, and pressure-resistant container.

The propellant is the driving force behind the spray, and sometimes doubles as a solvent or diluent for the drug. Pharmaceuticals are raw materials, which are liquid, semi-solid or solid powder. The valve system is different according to the product, there are ordinary valve, quantitative valve, foam valve. The most commonly used pressure containers are tin cans and aluminum cans.

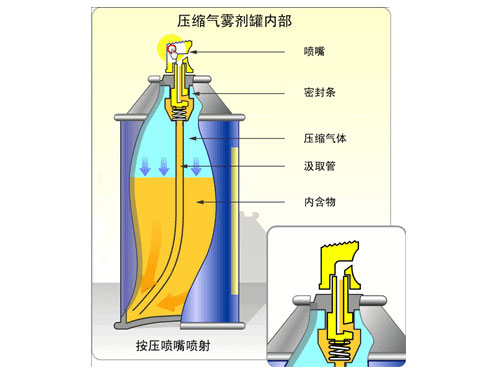

How aerosols work

The working principle of the aerosol is to fill the original liquid (active ingredient) with the liquefied gas or compressed gas into the aerosol canister at the same time, and seal it with a valve. When in use, press the actuator, the valve opens, and the liquid phase material in the tank is pushed upwards through the liquid pipe to the valve body under the action of the gas-phase propellant pressure, and then enters the valve core through the valve core metering hole to the actuator. ejected from the nozzle. The atomization process of the ejected material as it leaves the nozzle is the result of a combined effect. When it is ejected from the nozzle at high speed, it forms droplets due to the rapid vaporization of the propellant, and then the pressure of the liquid-phase propellant contained in the droplets disappears. , immediately evaporated into the gas phase. After the original liquid is discharged, the reduced volume in the aerosol can can be supplemented by the vaporization of liquefied gas, and the cycle continues until the original liquid is completely sprayed out.

If you rely on compressed air as the driving force of the original liquid, because this gas is almost insoluble in the active ingredient, when the active ingredient is pressed out of the aerosol can, it can completely maintain its original shape. When the liquefied gas is used in the aerosol can, the liquefied gas is partially vaporized in the sealed container, and most of the rest is still liquid and maintains a state of equilibrium. At this time, the gas phase is at the top of the tank, the liquid phase is at the bottom of the tank, and the active ingredients are dissolved or dispersed in the liquid phase. The gas phase exerts pressure not only on the tank walls, but also on the liquid. Therefore, when the valve is opened, the active ingredient can be pressed from the downwardly extending conduit to the valve outlet, and form a spray shape or foam shape when it is automatically pressed out, or it may be liquid or slurry, which is related to the nature of the pressurized substance as a driving force. and the structure of the valve.

If the boiling point of the liquefied gas used is much lower than the room temperature or ambient temperature, it can be vaporized immediately at this time, so that the active ingredients are sprayed into the air to form mist-like fine particles. If the active ingredient needs to be sprayed on the surface of the object to be applied, the aerosol must vaporize near or in contact with the surface of the object to be applied, leaving the active ingredient behind. This can be adjusted according to the different boiling points, dosage and consistency of solutes of various liquefied gases. Likewise, if the extrudate from the aerosol can is in the form of a foam, it differs primarily in that the foam product is a solution rather than an emulsion. When the valve is opened, due to the expansion of the liquefied gas, the emulsion produces many small bubbles, forming a foam shape. If the powder is suspended in the liquefied gas, when the valve is opened, the powder and the liquefied gas are sprayed out at the same time, the liquefied gas is rapidly vaporized and volatilized, and the powder remains on the surface of the object to be applied.